We provide services for M&E projects, building operations, and data centres.

We are pleased to provide guidance on your particular project and handle projects of all sizes, including commercial and industrial projects.Data center solutions encompass a broad spectrum of technologies and services designed to support the storage, processing, and dissemination of data within a secure and reliable environment.These solutions typically include robust infrastructure components such as servers, storage arrays, networking equipment, and power systems, all optimized for efficiency and scalability.

A security system encompasses various technologies and measures designed to protect people, assets, and premises from potential threats. It typically includes surveillance cameras, access control systems, alarms, and monitoring services.

These components work together to detect intrusions, monitor activities, and alert authorities or designated personnel in case of emergencies. Implementing a robust security system enhances safety, deters criminal activities, and provides peace of mind to occupants and stakeholders.

With encrypted communication channels and backup power sources, these systems prioritize reliability and resilience, delivering peace of mind by fortifying premises against unauthorized access and unforeseen incidents.

Distributor of card access systems. Offered in different specifications. System components include reader access control unit, wireless lock interface, contactless smartcard readers and credentials, wireless receivers and RF transmitters.

include design, installation, training, service, inspection, repairing, CAD engineering services, testing and maintenance. Used to control and monitor entry points include doors, elevator floors, parking gates and garage doors. 24 x 7 emergency services are available.

Parking access revenue, 2-door base, visitor management and web-hosted access control, visitor management and employee identification systems are available.

RB Tech is here to help you out with our fingerprint access installation service.Our installers not only install the same at the entry point of your building but also guide you into how you can customise the device, add and delete entries and maintain it efficiently.

Moreover, rest assured that our technicians will install the device accurately since they have years of experience in installing security systems in residential, commercial and industrial areas.

Finger Print devices are the modern tools that can keep your building safe from unauthorized entry. But since there are many devices each having different features, choosing the right one for your building can get a little bit confusing. So, besides providing the installation service,

RB Tech offers a comprehensive service that combines facial recognition solutions with an access control system. We only select equipment that delivers optimal performance. You can rest assured that our approach guarantees a heightened level of security, safeguarding your premises with cutting-edge technology.

The built-in body temperature sensor ensures that any person with a fever is prevented from signing in, and nominated staff are automatically notified immediately. These automated alerts ensure appropriate steps can be taken to maintain the health and wellbeing of all people on your premises.

All employees get their own LoopLearn web console to easily configure the LoopLearn system and see real-time attendance information and sign-in logs.

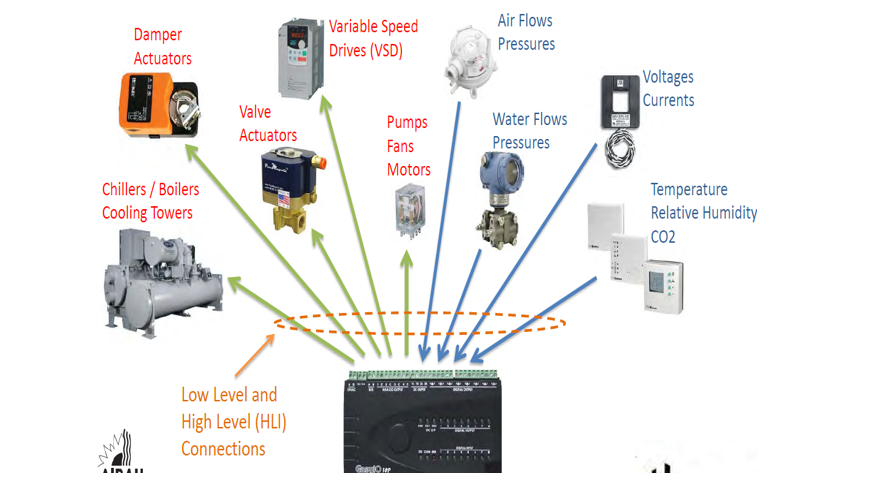

At BMS Engineering (A RB Tech in Singapore), we provide a one stop Building Management System (BMS) solution that aims to improve your building operations. Our solution is customizable to your specific needs and we are committed to helping you through this journey.

Aspiring to be one of the leading Systems Integrator of BMS, Integrated Facilities Management Systems and Energy Efficiency Solutions in the region, we will assist organisations to achieve high efficiency, flexibility and obtain cost savings through reduction of operational costs.

A Building Monitoring System (BMS), also known as a Building Management System or Building Automation System, is an integrated solution designed to monitor and control various building operations and systems.

EMS ensures optimal operational control of the power generation facilities with the linkage system through normal information collection and load frequency monitoring of the overall power supply system. With the efficient management of the power system, this large-scale power control system facilitates economic energy management.

Energy management system can help you to streamline and optimise your electrical systems by uncovering maintenance or upgrades that are needed in order to boost performance.EMS systems identify wasted resources and allow for better allocation of power – reducing any negative impact on the environment.

Moreover, an EMS includes alerts and notifications to promptly inform operators of any abnormal conditions or failures. This feature is crucial for maintaining the reliability and safety of the electrical power network.

With 20 years of professional experience, Electrical Testing Services is proud to serve the entire of singapore with quality electrical services for residential and commercial customers.

Whether you need the installation of a new electrical system, have any minor repairs, maintenance, retrofits, or any other electrical issue, we are well-equipped to help you. Testing your electrical appliances for faults and damages ensures the safety of the people in the workplace who come into contact with the appliance.

Within buildings or facilities, the electrical system further distributes electricity through switchboards, panel boards, and distribution boards. These components control and direct power to various circuits, outlets, and appliances, ensuring safe and efficient electricity usage.

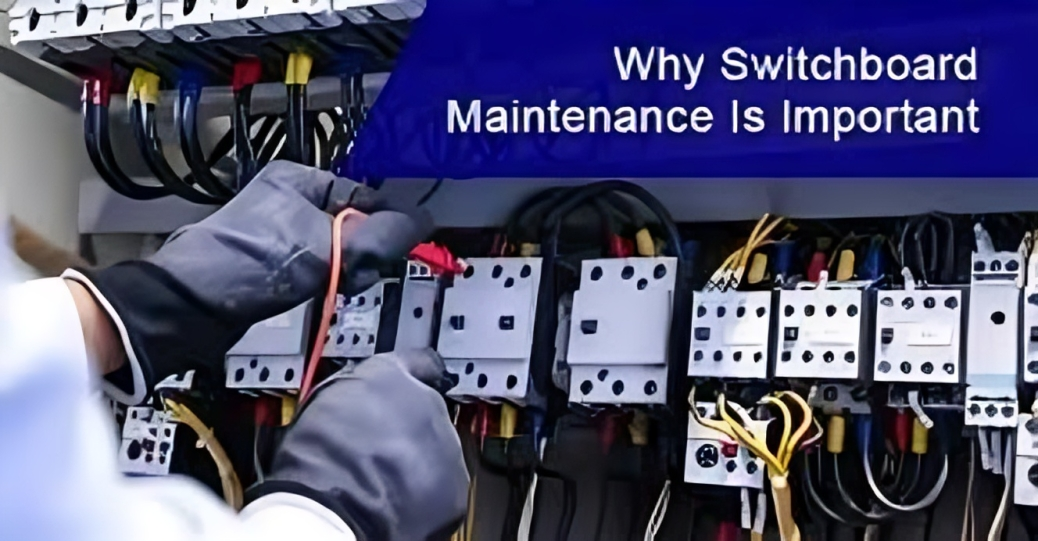

Electrical switchboard installation, preventive maintenance servicing, and troubleshooting are critical aspects of ensuring safe and efficient electrical systems in residential, commercial, and industrial settings.

Preventive maintenance servicing plays a crucial role in extending the lifespan of switchboards, involving regular inspections, testing of connections, cleaning of components, and ensuring compliance with safety standards.

Troubleshooting procedures are indispensable in resolving switchboard malfunctions swiftly. Thorough analysis using electrical diagrams pinpoints faults, prompting detailed component examinations for visible signs of damage.

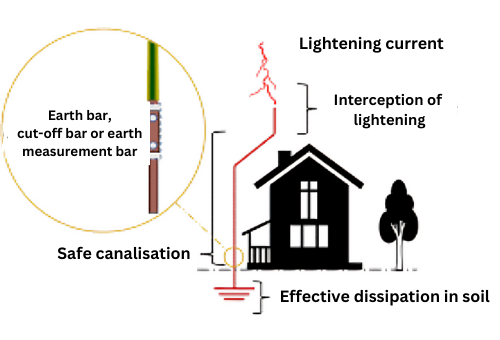

Earthing and lightning protection systems are critical components of any infrastructure to ensure the safety of personnel and equipment against electrical faults and lightning strikes. Installation of these systems involves meticulous planning and adherence to safety standards to achieve effective grounding and protection.

Proper preventive maintenance servicing is essential to maintain the integrity and functionality of earthing and lightning protection systems over time. This includes regular inspections, testing of grounding resistance, and verification of lightning conductor continuity.

Scheduled inspections are conducted to assess the condition of lightning protection components, such as lightning rods, conductors, and grounding systems.After installation, the entire system is thoroughly tested to ensure compliance with standards and regulations. This includes resistance testing of grounding electrodes and continuity testing of conductors.

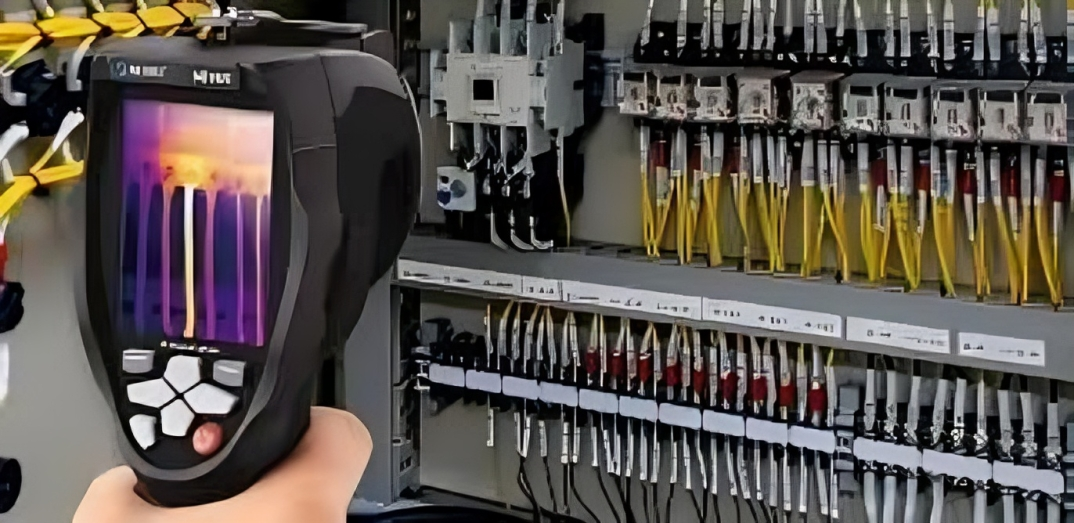

Thermal scanning of switchboards is a crucial practice in ensuring the safety and reliability of electrical systems. By using infrared thermography, technicians can detect abnormal temperature patterns that might indicate overloaded circuits, loose connections, or faulty components within switchboards.

This non-invasive method helps identify potential issues before they escalate into major failures or hazards, allowing for proactive maintenance and minimizing downtime.

Regular thermal scanning not only enhances the operational efficiency of switchboards but also contributes significantly to overall electrical safety protocols, ensuring compliance with regulatory standards and promoting a secure working environment for personnel.

A mechanical system refers to a collection of interconnected mechanical components that work together to perform a specific task or function. These systems can range from simple mechanisms, like a bicycle's chain and gears, to complex industrial machinery used in manufacturing processes.

The efficiency and reliability of mechanical systems depend on precise engineering design, proper maintenance, and understanding of the principles of mechanics governing their operation.

Mechanical systems often involve the transfer of energy from one form to another. For example, a steam engine converts thermal energy into mechanical work, while an electric motor converts electrical energy into mechanical motion.

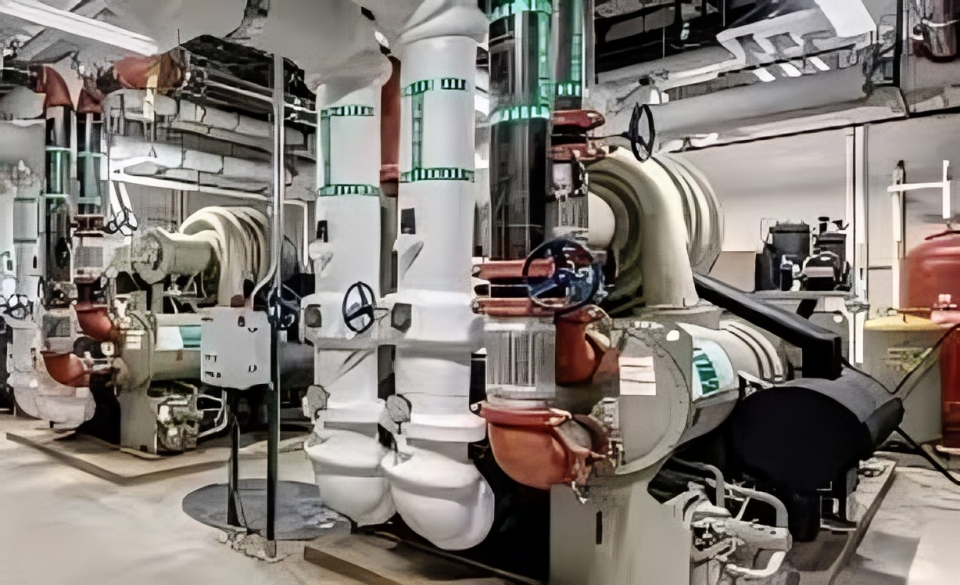

Chiller installation, preventive maintenance servicing, and troubleshooting are critical aspects of ensuring optimal performance and longevity of HVAC systems. Proper installation involves meticulous attention to manufacturer specifications and local building codes to guarantee safety and efficiency.

Troubleshooting chiller issues requires skilled technicians adept at diagnosing problems such as leaks, inadequate cooling, or electrical faults swiftly and accurately, using diagnostic tools and industry best practices.

Proper installation, preventive maintenance, and troubleshooting are vital for the efficient and reliable operation of chillers. A well-maintained chiller system not only ensures optimal performance but also extends the equipment's lifespan and reduces operational costs.

Key considerations during installation include site selection for efficient airflow, accessibility for maintenance, and integration with existing infrastructure. Proper assembly of structural components and precise alignment of plumbing and electrical connections are crucial to achieving seamless operation from the outset.

Preventive maintenance is essential to uphold the efficiency and reliability of cooling towers. Regular inspections and cleaning of components such as fans, motors, and fill material help prevent debris buildup and mechanical wear.

The location of the cooling tower is crucial for its performance. The site should provide ample space, good airflow, and accessibility for maintenance. It should also be structurally capable of supporting the tower's weight and isolating vibrations.

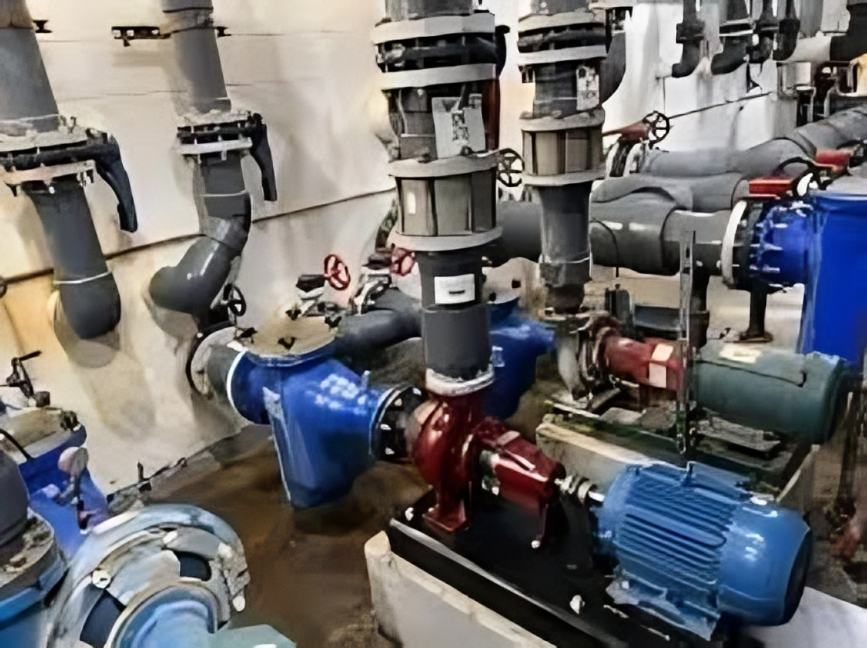

Pump installation, preventive maintenance servicing, and troubleshooting are critical aspects of ensuring efficient and reliable pump operation across various industrial and commercial applications. Proper pump installation involves careful consideration of factors such as pump location, alignment, and foundation to minimize vibration and ensure optimal performance.

Preventive maintenance servicing plays a crucial role in extending pump lifespan and reducing unexpected downtime by regular inspection, lubrication, and replacement of worn-out components like seals and bearings.

Proper piping is essential for efficient pump operation. Ensure that the suction and discharge pipes are correctly sized and aligned to prevent stress on the pump casing. Use flexible connectors to accommodate thermal expansion and vibrations.

preventive maintenance servicing, and troubleshooting of FCU (Fan Coil Unit) or air conditioning units are essential for maintaining optimal indoor air quality and comfort. Connection of FCUs or aircon units to ensure efficient airflow and temperature control throughout the designated space.

Preventive maintenance servicing is crucial in prolonging equipment lifespan and reducing energy consumption by regularly cleaning filters, coils, and condensate drains,inspecting and tightening electrical connections.

Fan Coil Units (FCUs) and air conditioning (aircon) units are essential components in HVAC systems, providing temperature control for indoor environments. Proper installation, preventive maintenance, and troubleshooting are crucial to ensure these units operate efficiently and reliably.

A fire alarm system is a crucial component of any building's safety infrastructure, designed to detect and alert occupants to the presence of fire or smoke. These systems consist of various interconnected devices such as smoke detectors, heat detectors, fire alarms, and manual call points strategically placed throughout the premises. Upon detecting a potential fire hazard, the system triggers alarms to notify building occupants, enabling swift evacuation and response by emergency services.

Effective installation, preventive maintenance, and troubleshooting are essential for the reliable operation of fire systems. Regular maintenance ensures optimal performance, extends the lifespan of the equipment, and enhances safety.By addressing issues promptly and following a systematic approach, fire systems can provide effective protection for lives and property in the event of a fire.

smoke and heat detectors is a critical step in establishing a comprehensive fire detection system within buildings. Smoke detectors are designed to sense the presence of smoke particles, while heat detectors respond to changes in temperature indicative of a fire.

Troubleshooting is crucial in identifying and rectifying issues promptly, such as sensor malfunctions, wiring faults, or power supply issues, which could compromise the system's reliability.

Install smoke detectors in areas where smoke is likely to travel, such as hallways, stairwells, and near sleeping areas in residential settings. Heat detectors should be placed in areas prone to temperature rises, such as kitchens, mechanical rooms, and attics.

Gas suppression systems, such as N2, FM200, and Inergen, are vital components of fire protection strategies in environments sensitive to water damage or where rapid fire suppression is critical. Installation of these systems involves careful planning and adherence to industry standards to ensure effective coverage of the protected area.

Preventive maintenance is essential to uphold system reliability, involving regular inspections, functional testing of release mechanisms, and monitoring of pressure levels in storage containers to ensure readiness in the event of a fire emergency. Troubleshooting should follow a systematic approach, starting with the most common and easily identifiable issues before progressing to more complex diagnostics. Document findings and actions taken to build a history that can help with future troubleshooting.

Wet and dry sprinkler suppression systems are fundamental in fire protection, each designed to deploy water swiftly in response to a fire emergency. Wet systems maintain pressurized water in piping connected to sprinkler heads that activate individually when heat triggers them, immediately releasing water onto the fire.

Dry systems, on the other hand, use pressurized air or nitrogen to keep water out of the pipes until a fire activates the sprinkler heads, allowing water to flow into the affected area. Installation of these systems requires meticulous planning to ensure adequate coverage and compliance with safety regulations.

Connect the system to a reliable water supply, such as a municipal water main or a dedicated fire pump and water storage tank. Ensure that the supply can provide adequate pressure and flow for the system.

Public Addressing Systems (PA Systems) are crucial installations in facilities where clear and effective communication is essential for safety and operational efficiency. Installation of PA systems involves strategically placing speakers and amplifiers throughout the premises to ensure comprehensive coverage and clear audio transmission.

By adhering to meticulous installation practices, conducting routine maintenance, and promptly addressing any operational challenges, PA systems enhance communication capabilities, facilitating orderly evacuations and critical announcements in public and private settings alike.

Install the control unit and amplifiers in a central, easily accessible location. Ensure proper ventilation to prevent overheating and interference from other electronic devices.

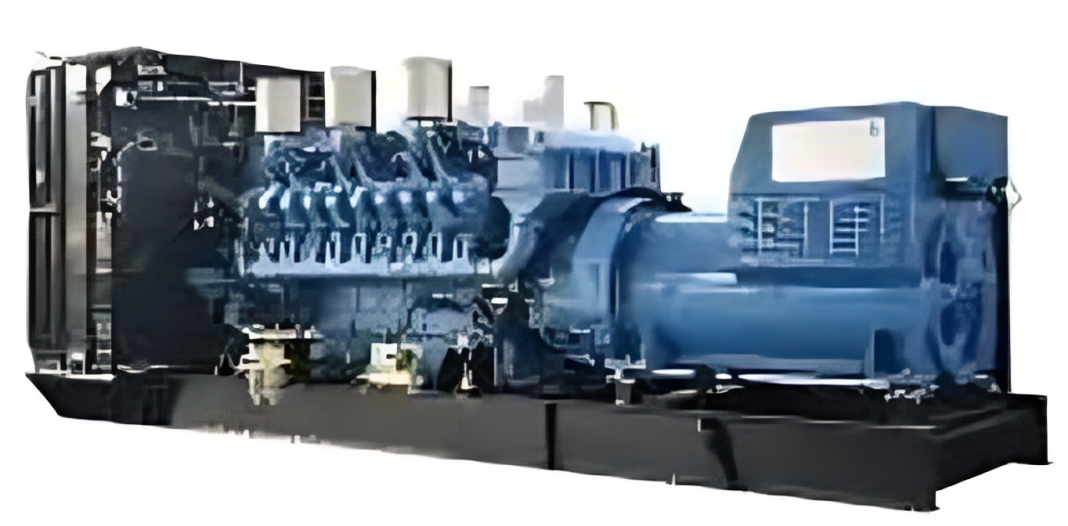

Generators and UPS (Uninterruptible Power Supply) systems are critical components in ensuring continuous power availability for various applications. Generators are robust, often diesel or gasoline-powered machines that generate electricity when the main power source fails.

They are essential for environments requiring sustained power, such as hospitals, data centers, and industrial facilities. UPS systems, on the other hand, provide immediate backup power during brief outages or until a generator kicks in.

Generators are mechanical devices that convert mechanical energy, typically from combustion engines fueled by diesel, natural gas, or gasoline, into electrical energy. They are designed to provide backup power during outages or in areas where grid power is unreliable.

Regular preventive maintenance servicing and effective troubleshooting are indispensable practices for ensuring the reliability and longevity of generator systems. Scheduled maintenance includes inspections, oil and filter changes, fuel system checks, and testing of critical components such as batteries and coolant systems.

Troubleshooting involves systematic diagnostics to pinpoint and resolve faults swiftly, ensuring minimal downtime. Technicians are trained to address common issues like fuel supply problems, electrical faults, or mechanical malfunctions promptly, employing diagnostic tools and expert knowledge to restore functionality efficiently. Smaller in size and often portable, gasoline generators are suitable for residential use or smaller commercial needs.

Static UPS (Uninterruptible Power Supply) involves meticulous planning and execution to ensure seamless integration with existing electrical systems. This typically includes site surveys, electrical load assessments, and placement considerations to optimize efficiency and accessibility for maintenance.

Effective troubleshooting protocols ensure uninterrupted power supply during critical operations, reinforcing the dependability of Static UPS systems in safeguarding sensitive equipment from power disruptions.

Generators are installed outdoors or in well-ventilated areas due to exhaust emissions. Proper ventilation and compliance with local codes are essential.

Dynamic Rotary UPS (DRUPS) systems are advanced solutions for ensuring continuous power supply in critical environments where even the briefest interruption can have significant consequences. Unlike static UPS systems, DRUPS utilize kinetic energy stored in flywheels or rotating masses to provide immediate backup power during electrical disruptions.

Regular inspections, lubrication of mechanical components, and monitoring of flywheel condition are critical tasks to prevent potential failures. Scheduled servicing also includes checks on electrical connections, cooling systems, and control circuitry to maintain peak efficiency. Conduct routine inspections of all DRUPS components, including rotary converters, static inverters, batteries (if applicable), control systems, and cooling mechanisms.

Plumbing and sanitary systems are fundamental components of any modern building infrastructure, ensuring the safe and efficient distribution of clean water and the proper disposal of wastewater. Plumbing involves the intricate network of pipes, valves, fittings, and fixtures designed to transport potable water for various uses such as drinking, bathing, and cooking.

Sanitary systems, on the other hand, focus on the effective removal and treatment of sewage and wastewater to prevent contamination and maintain public health standards. Located at various points to control water flow. Main shut-off valves allow for complete water supply shutdown in emergencies or during repairs.

maintenance of water pumps, pipes, and meters are crucial for ensuring reliable water supply and efficient usage within residential, commercial, and industrial settings. Water pumps are essential for boosting water pressure and distributing water from its source to various points of use.Provide a stable foundation or base to support the pump and dampen vibrations.

This involves conducting thorough inspections, using diagnostic tools, and applying appropriate repair techniques to restore functionality and prevent further damage. Install the pump in a dry, well-ventilated area, preferably close to the water source. Ensure accessibility for maintenance and repairs.Connect inlet and outlet pipes to the pump, ensuring proper alignment and sealing with appropriate fittings.

Building services encompass a broad range of systems and facilities essential for the functionality, comfort, and safety of any built environment. These services typically include electrical, mechanical, plumbing, and HVAC (heating, ventilation, and air conditioning) systems, among others.

Effective design, installation, maintenance, and integration of these services are paramount to supporting the functionality and sustainability of modern buildings, meeting regulatory standards, and enhancing user comfort and safety. Controls indoor climate through heating, cooling, and ventilation systems. Includes boilers, chillers, air handling units, ductwork, and thermostats.

Data cleaning is a critical process in data analysis and management, involving the identification, correction, and removal of inaccurate, incomplete, or irrelevant data. This meticulous process aims to improve data quality and integrity, ensuring that datasets are reliable and suitable for analysis or decision-making purposes.

It is a foundational step in the data lifecycle, essential for organizations to derive meaningful conclusions, make informed decisions, and maintain operational efficiency across various sectors including finance, healthcare, marketing, and beyond.

In some cases, data might need to be transformed into a different format or structure to facilitate analysis or integration with other datasets. This could include aggregating data, reshaping it for specific analytical tools, or converting between different data types.

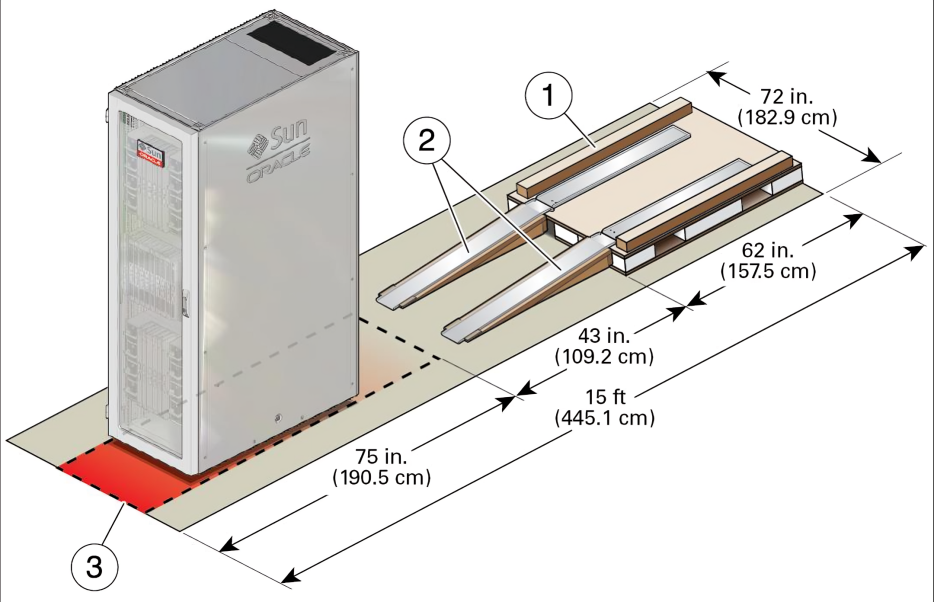

Loading and unloading servers in a data center is a meticulous process crucial for maintaining uninterrupted operations. Careful planning and execution are essential to ensure efficiency and prevent downtime.

During loading, servers are transported to their designated racks or positions within the data center. This involves verifying specifications such as power requirements, network connectivity, and physical dimensions to ensure compatibility with the designated location

Servers are physically placed into the designated slots or bays within the rack. Each server is carefully mounted to ensure proper alignment and to avoid any damage to the equipment.

Minor construction or modification works in buildings involve a range of tasks aimed at enhancing functionality, aesthetics, or compliance with updated regulations.

These projects typically include activities such as interior partitioning, installing new fixtures, upgrading electrical or plumbing systems, or making structural adjustments that do not fundamentally alter the building's footprint or load-bearing capacity. The process begins with detailed planning and obtaining necessary permits or approvals, followed by careful execution to ensure minimal disruption to occupants and surrounding areas.

Depending on the scope of the work and local regulations, permits and approvals may be necessary before proceeding. This ensures compliance with building codes, safety standards, and environmental regulations.