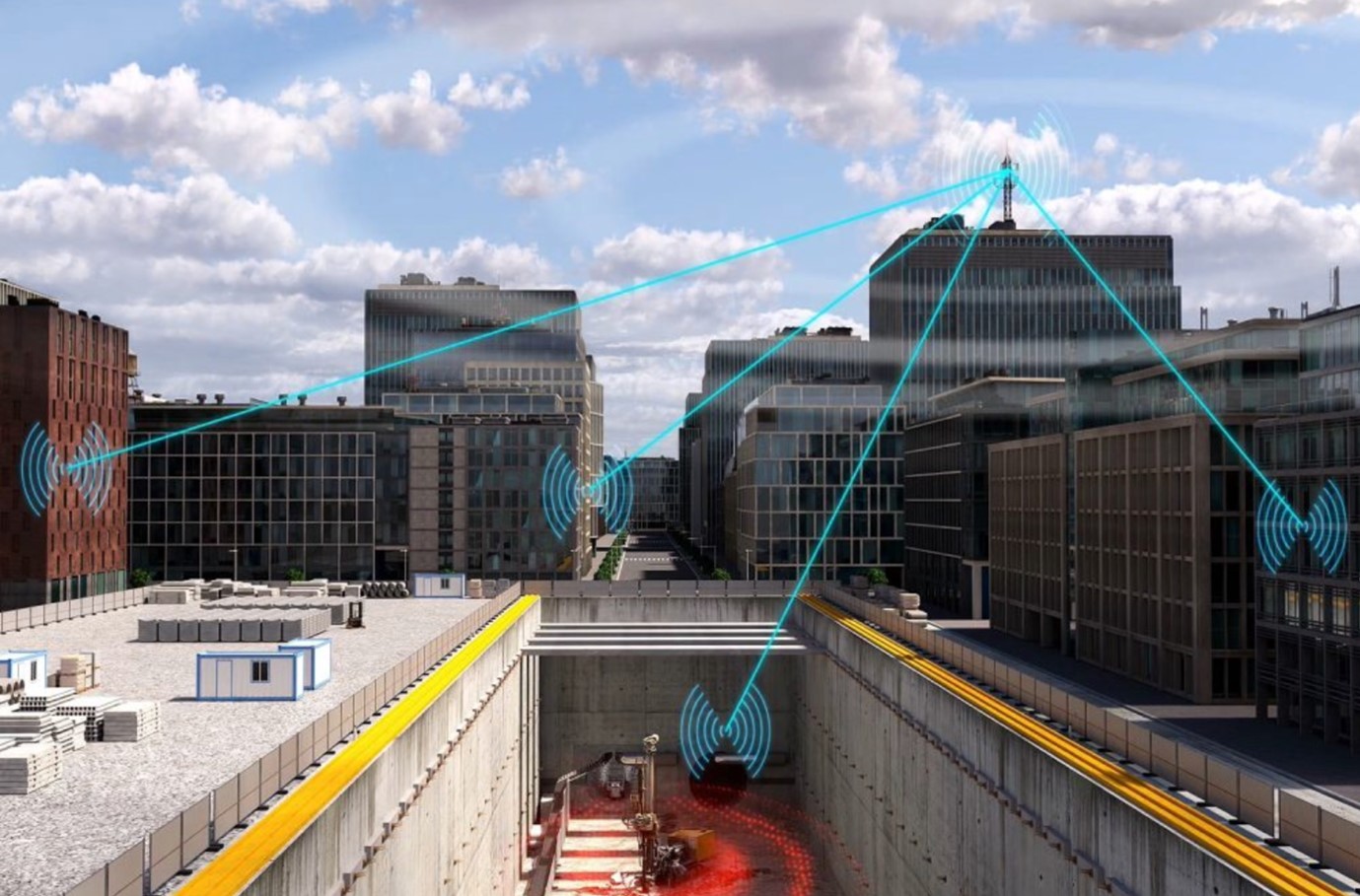

When equipment is unable to run during normal operating hours, production declines, and the organization loses money. We use remote condition monitoring systems in industries such as oil, gas, petroleum, and data centers to prevent this, as well as to increase safety, dependability, and efficiency. The ability to measure and monitor machine status, performance, and behavior from a distinct location is known as remote monitoring.

Introducing remote machinery monitoring services in predictive maintenance in the industrial maintenance arena has been game-changing and revolutionary. Professionals in charge of minimizing plant downtime can now use remote condition monitoring to monitor assets on-site and reduce unplanned downtime. This is how RB Tech & Engineering's expertise in preventative maintenance can assist you.

RB Tech & Engineering supplies remote vibration and temperature monitoring products that are industry-standard and have a proven track record. Our customers will have complete information about the health, performance, and stress levels of their equipment with these items. We’ll notify you every time our cutting-edge remote monitoring system discovers a fault or irregularity; it immediately delivers an alarm message to the maintenance team, allowing them to perform timely maintenance measures and improve the machine’s health.